ARTICLES Strawbale Construction - Low Tech vs. High Tech or Just better physical properties? Ken Haggard, 1. Introduction Invented by pioneers in the great plains of North America in the 1890s, strawbale construction techniques have been resurrected during the last ten years. Strawbale construction generally consists of stacking standard size agricultural bales to form the exterior walls of buildings. These walls are then sealed by stuccoing both the inside and outside of the walls. Walls of this sort can be used as infill, within a separate structural frame or with some engineering they can become the building’s structure as well as the building envelope. In California, we have permitted and built stuccoed strawbale walls that handle both gravity and seismic loads without additional structural elements and several of these have done very well in recent earthquakes. In these cases the stucco skin acts as a thin shell with its adhesion to the bales preventing local buckling of the shell.

| Figure 1: Constructing an infill strawbale building. |

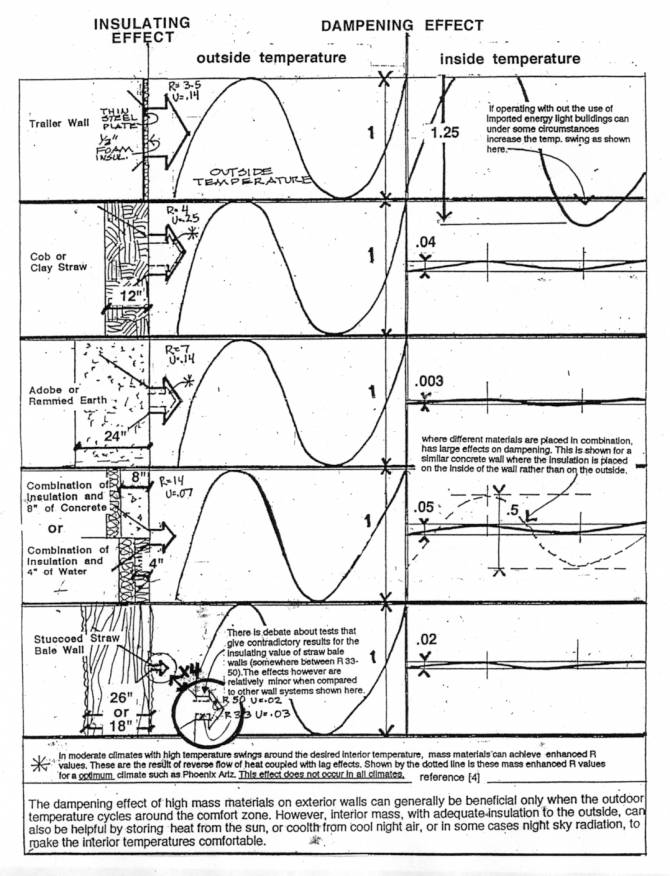

Recent applications have used bales with standard platform framing to produce multistory bale buildings. There is also a lot of work occurring using other methods of sealing the bales such as lime and earthen plasters. Since the rediscovery of this approach to building about 10 years ago, thousands of strawbale buildings have been built worldwide. For example, there are at least sixty in our county alone on the central California coast. Strawbale construction has been described as a romantic low tech fashion by many industrial oriented builders and architects but the advantages of this type of construction is that it offers a better physical response to many of today’s building needs. This article will discuss some of these advantages starting at the larger scale of concerns and going to the smaller ones. 2. Planetary Scale We raise most grain on an industrialized basis, which results in a great concentration of straw once the grain is removed. This straw, particularly rice straw, is very tough and hard to compost and is therefore considered a troublesome waste product. Growers have been getting rid of rice straw by burning it but this produces prodigious amounts of air pollution and adds to the CO2 load in the atmosphere. Increasing regulation to prevent this method of disposal has developed but a more positive solution is to creatively use this straw. Constructing buildings from straw, particularly rice straw, is one of these creative approaches for the properties that make this material troublesome also make it a superior building material. Strawbale construction (see Figure 1) allows a better building while simultaneously having less impact on the planet. Pollution isn’t produced from burning and carbon is sequestered in the new buildings rather than contributing to climate change. If we do this on a large enough scale, we can also reduce the pressure on our forests, which in their turn also sequesters carbon, cleans air, creates healthy watersheds and provides beautiful environments and wildlife habitat. Performance prediction models like Energy 10 begin to allow us to calculate many of these benefits so that they can become part of life cycle design and analysis of a building. This type of information can be used in green building certification programs like LEED (Leadership in Energy and Environmental Design) created by the U.S. Green Building Council to document the benefits and true costs of a Green Building. 3. User Scale A strawbale building provides a very different feeling from standard buildings. This is because thick walls are so rare in industrial era architecture which generally uses relatively thin materials such as steel, plywood or concrete panels. Many people like the substantive feeling of the thick walls, deep inset doors and windows, window seats and handy niches that can result. Since the strawbales are easy to carve and restring they offer unique aesthetic opportunities. The more complex geometry of curves can become part of the building composition at little extra cost. Curving the walls and carving the ends are easily accomplished with such simple tools as chainsaws and bale-saws. Interplaying complex shapes with a feeling of solidity are natural aesthetic directions with strawbale construction technology. Another consideration at the user scale is concern with indoor air pollution caused by building with inherently unhealthy materials. Various insulations, adhesives, and many paints have traditionally been the culprits in this situation. Strawbale construction eliminates much of the more industrial based insulation and if one uses a fine gypsum finish for the finish coat of the interior stucco wall, we can eliminate the need for paint on large areas of the building. Simplifying the building components to just bales and stucco reduces the need for glue and caulking in many areas as well. A simple experimental test of the difference in this regard is to visit a standard residence during construction after the insulation, wiring, windows, etc. have been installed. One usually will experience a tightening of the throat and other subtle discomfort. This is because there is so much toxic material being used in the interior, soon to be living space. A visit to a strawbale building at this phase of construction will be a different experience. The biggest area of potential improvement in strawbale construction in regard to health is to reduce the use of Portland cement to a minimum. This is because large amounts of Carbon Dioxide is added to the atmosphere by the manufacture of cement. This is why a lot of work is being done with lime and earthen plasters for strawbale construction. Philsophical concerns and ease of construction with friends and neighbors meant that the first of this new generation of bale buildings were simple small residences. Over the last several years however strawbale construction has spread to larger, fancier residences. Recently strawbale construction is starting to be used for part of green public buildings such as places of worship, and education facilities. 4. Building Scale Compared to standard residential construction, strawbale buildings have better insulation qualities resulting in a quieter and more thermally efficient indoor environment. A standard strawbale wall provides about three times the insulation value of a standard stud wall with fiberglass insulation (R-30 vs. R-11). There have been some interesting recent approaches to using bales for roof components to increase roof insulation as well. Strawbale walls are more fire resistant than standard wood frame construction. The stucco coating on the interior and exterior of the bales prevents oxygen from reaching the compact cellulose of the bales in quantities that allow rapid combustion. Burning a bale is like trying to burn a dense stack of phone books. Bale walls have a two hour fire rating in most building applications while by contrast we have to use two layers of special 5/8” gypsum board to get a one hour rating with standard wood framing. Strawbale components have additional advantages if we look at the building as an integrated thermal whole. The increased insulation of the wall and the distributed thermal mass of the stucco interior skin work together to help create a passive solar building. A passive solar building is one that is properly oriented and tuned so that it largely heats and cools itself using intelligent proportions of sun, shade, cool night air, thermal mass and insulation. If done correctly, a passive solar building can provide greater comfort at less cost and more security since the amount of energy needed to be imported to the site to operate the building is greatly reduced (see Figure 2).  Figure 2: Passive solar strawbale building design in Santa Margarita, Ca. 5. Component Scale Building walls have traditionally been thought of as a simple element that serves only one discrete function. However, strawbale construction, once stuccoed, is a composite that can serve several functions, besides just being a building envelope. Functions important to a passive solar building involve providing insulation and thermal mass. The differences between these are often confused in the building industry. Insulation is what moderates heat flow in and out of the building. It is analogous to resistance in an electrical circuit. Thermal mass is different. Thermal mass holds heat or coolth and thus moderates the temperature swing in a building. It is analogous to a capacitor in an electrical circuit. It just happens that a stuccoed strawbale wall has for many temperate climates an optimal relationship between this insulation to reduce heat flow, and thermal mass to moderate interior temperature swings. Since thermal mass is expensive it needs to be used most efficiently. For a passive buildings that involves both solar heating and night ventilation cooling in many temperate climates two inches of distributed masonry is close to optimal. This is very close to what occurs in the three coat stucco finish on the interior of a strawbale wall. The relationships, between insulation and mass is shown comparatively for various building systems in Figure 3. It shows why strawbale building technology is such a good fit for passive solar buildings. An additional advantage of strawbale construction deals with maintenance and longevity. As mentioned before there are 110 year old strawbale buildings still in use. Stucco traditionally applied to plywood panels in light frame construction experiences a lot of cracking. This is because the coefficient of expansion of the two materials is different. Plastered strawbale construction has less cracking because the expansion and contraction of the stucco is not in conflict with that of the straw upon, which it is applied. The straw is flexible enough to move with the stucco while still providing excellent “tooth” for the stucco layer to attach to. 6. In Summary Strawbale construction has many advantages in contemporary construction when its unique physical properties are taken advantage of. In spite of being considered by some as being a romantic low-tech fad, it has very specific advantages regarding waste, energy and construction processes. This type of building technology is a part of our transformation from highly developed but depleting industrial processes to information-based sustainable processes. This is a transformation that is occurring in many fields, besides architecture and it is critical to our future.

Figure 3: Insulating Effect and Relative Temperature Dampening Effect Ken Haggard San Luis Sustainability Group Architects 16550 Oracle Oak Way Santa Margarita, CA 93453 E-mail: SLOSG@slonet.org Phone: (805) 438-4452 Fax: (805) 438-4680 www.slosustainability.com |