Film Instabilities in Microchannels

Thomas Cubaud (tcubaud@ms.cc.sunysb.edu)

Department of Mechanical Engineering, Stony Brook University, Stony Brook, NY 11794-2300

http://me.eng.sunysb.edu/~microfluidics/

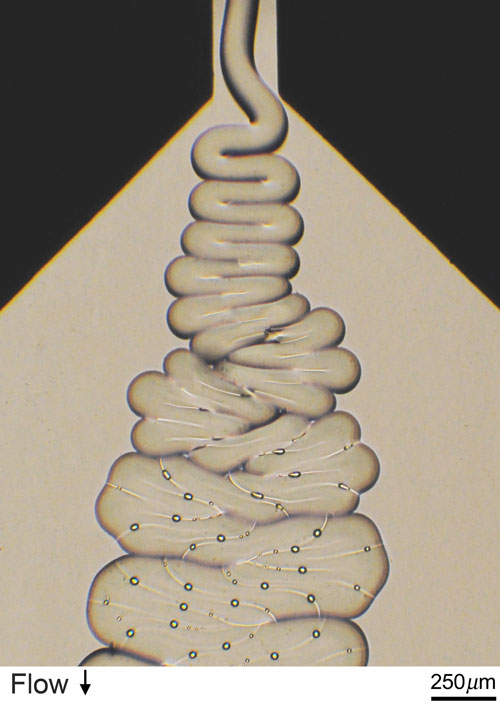

Figure 1: Formation of droplets (ethanol) during the folding instability of a capillary viscous thread (silicone oil) in a diverging slit microchannel. The thread deformation introduces variations in the thickness of the sheath fluid’s film between the thread and the top and bottom walls (glass); the film ultimately ruptures into droplets along coalesced folds.

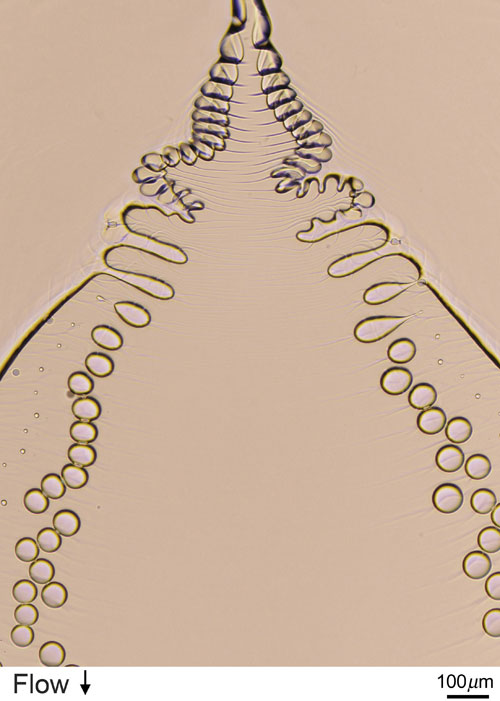

Figure 2: Formation of droplets due to the interplay between the dynamic wetting of the sheath fluid (silicone oil) at the top and bottom walls (glass) and the lubrication failure of a capillary viscous thread (mineral oil) in a diverging slit microchannel.

Detailed Description

These droplet-decorated streams are observed through the glass of a diverging microchannel. Microfluidic devices allow for exploring original fluid interactions far from equilibrium. Here, a combination of hydrodynamic instabilities is used for continuously producing droplets. Upstream (top), a thread made of viscous fluid flows in the center of a square channel. The thread is surrounded in a sheath of immiscible, less viscous fluid at the walls. Downstream, the thread buckles and feeds a slowly moving pile, which is in contact with the glass walls of the diverging channel. In the contact region, droplets form due to the inclusion of the ensheathing fluid into the pile. Figure 1 displays tiny droplets sliding on tracks. The thread’s buckling deformations create local variations of the less viscous fluid’s film thickness at the walls. When the film is thin enough, it destabilizes and ruptures, or “dewets”, into droplets. Figure 2 shows the side embedding of droplets into the pile. This phenomenon results from the interplay between the fluids’ partial wetting of the walls and the thread’s lubrication failure. These images show the possibility to structure microflows and illustrate the importance of solid walls confinement and material properties on microscale multi-fluid dynamics.

This research was supported the Dept. of MEC and CEAS at Stony Brook University.

These images have not been published.