The Future of Low-Carbon Transportation Fuels

Articles

Christopher Yang and Sonia Yeh

[Editor’s note: This article is an abridged version of a paper presented at a conference on the physics of sustainable energy held at UC-Berkeley in March 2011. A review of the conference proceedings was published in the April 2012 edition of P&S.]

Introduction

According to the Energy Information Administration’s Annual Energy Outlook projection, petroleum fuel uses make up essentially all transportation fuel usage today and will continue to account for 95% of transportation fuel usage in 2035 if we continue on our current path [1]. Biofuels are projected to make up the largest increase in the use of alternative fuels, to about 4% of fuel usage in 2035. As is well-known, fossil fuel use has many economic and environmental impacts, including reliance on imported energy sources that weakens our energy security, air pollution, and greenhouse gas (GHG) emissions that contribute to climate changes.

In this article we qualitatively examine the possibilities for low-carbon transportation fuels. Specifically we consider biofuels, electricity and hydrogen as displacers of petroleum-based fuels. The discussion here focuses on fuels, though fuels such as electricity and hydrogen are intimately tied to the vehicle platform and their success will be influenced by the success of the other. We will emphasize fuels for light-duty vehicles (passenger cars and trucks), which make up around 55% of energy use in the transportation sector. We will discuss the transition challenges to alternative fuels, particularly the infrastructure challenges, and the issues of making a transition to sustainable transportation over the long run.

Biofuels as Transportation Fuel

While biofuels can comprise a range of forms including liquids, solids and gases, we will focus only on high energy-density liquid fuels to be used as substitutes for petroleum-based fuels. As shown in Table 1, biofuels can be produced from a wide array of potential feedstocks and technology. Thus, biofuels can have potentially very different fuel properties, energy use, emissions, and environmental effects throughout their production lifecycle.

Table 1. Biofuel feedstock and production pathways. Adapted from Parker et al. [2]

| Feedstock category | Feedstock type | Conversion technologies |

| Starch & sugar-based biomass | Corn, sugarcane, sugar beet, sweet sorghum | Bioethanol through hydrolysis & fermentation |

| Ligocellulostics | Forest biomass, herbaceous energy crops, agricultural and food production residues, municipal solid wastes | Cellulostic ethanol through hydrolysis and fermentation; upgrading of pyrolysis oils to gasoline; Fischer-Tropsch diesel |

| Lipids | Seed oils, yellow grease, animal fats | Fatty acid to methyl esters, hydro-treatment of fatty acids to hydrocarbons |

| Algae | Transesterfication |

Biomass feedstocks for liquid fuel production can be categorized into four types: lignocellulosic biomass, sugars/starches, oils and animal fats, and algae. These feedstocks can come from a variety of sources including grain-based crops (such as corn or soy), oilseeds and plants (such as oil palm and sugarcane), agricultural residues, energy crops, forestry resources, industrial and other wastes, and algae. The technology for the conversion of these feedstocks to a liquid fuel can also take several different forms, including biological, chemical and thermochemical processing (Table 1). First generation biofuels, those that are commercially available today, include sugar- and starch-based ethanol (a gasoline substitute) and vegetable oils and biodiesel, which are diesel substitutes. Advanced biofuels are derived from processes currently in development and include alcohol fuels from cellulose, algal-based fuels, and thermochemical conversion of biomass to hydrocarbon that can be converted to a full range of fuels including gasoline, diesel fuel and jet fuel that meet the same specifications as today’s petroleum fuels.

Conversion of biomass into a biofuel can take many forms. Commercially available conversion processes used for first generation biofuels include biological fermentation (via yeast) of sugars into ethanol, and chemically catalyzed transesterification of oils/fats and alcohols into biodiesel. More advanced processes are currently being developed, including ethanol production from lignocellulosic biomass (wood, grass, and straw), thermochemical conversion of lignocellulosic biomass via gasification, a Fischer-Tropsch synthesis process to produce diesel fuel, and algae biofuels, which require development of cultivation, separation of cells and oils and conversion to useful fuels.

While biomass resources are plentiful, not all are technically, economically and environmentally viable for conversion to transportation fuels. Limitations on sustainable biofuel supply will play an important role in determining the extent to which petroleum fuels can be displaced by biofuels, as will limits on the use of specific biomass resources because of sustainability concerns [3]. Estimates of US biomass indicate that it could be sufficient to supply somewhere around 80-100 billion gallons of gasoline equivalent per year. Depending upon vehicle efficiency and projections of future travel demand, this could correspond to anywhere from approximately 1/3 of transportation fuel demand in 2050 in a business-as-usual scenario to nearly all liquid transportation fuel demand in a highly efficient and electrified demand future [4].

The sustainability of biofuels is an important question and is dependent on the specific feedstock to produce the biofuel. While there is no agreed-upon definition of sustainability, many different metrics and potential impacts have been proposed: ecosystem/habitat disruption, deforestation, soil quality impacts, net GHG emission reductions, air and water pollution, water usage, competition with food crops that leads to high food prices, and land rights and labor issues [4]. These impacts are important to quantify because, if not done carefully, they can negate or even exceed the environmental benefits that using biofuels is supposed to provide.

While some transportation modes can be electrified (such as light-duty plug-in electric vehicles or fuel cell vehicles), other modes, specifically aircraft, marine shipping, and heavy-duty trucks are most likely to use liquid fuels for the next few decades because of vehicle range and fuel energy density issues. Given that these modes are projected to have significant travel demand growth [1], a low-carbon biofuel is perhaps the only option for lowering the GHG intensity in these transportation modes.

Electricity as a Transportation Fuel

Plug-in electric vehicles (PEVs) are powered, at least in part, by electricity from the power grid that is stored in an onboard battery. They can be either plug-in hybrid electric vehicles (PHEVs), which can run on electricity or gasoline, or battery electric vehicles (BEVs), which run entirely on electricity. PEVs operating on electricity are much more efficient than conventional internal combustion engine vehicles (ICEVs) running on petroleum fuels. PEVs are beginning to be commercialized in 2011 but as yet make up a tiny fraction of vehicle sales.

While batteries are the key technology for the success of PEVs, the electricity supply and infrastructure side of the equation is also important to understand from a technology and deployment perspective.

PEVs need to be plugged in to "refuel" the onboard batteries, which can store an amount of energy of from about 3 kWh for a low-range PHEV to over 50 kWh for a longer range BEV. While current PEVs can be recharged at a conventional 120V outlet (often called level 1 charging), the rate of energy transfer is quite slow (~1-2 kW). To recharge more quickly it is necessary to use higher voltage and current and a dedicated PEV charger. Level 2 charging is 240 V and up to 40 amps for up to 9 kW, while level 3 charging is being designed to allow for very fast charging (up to 80% of battery capacity in less than 30 minutes).

Given the low penetration of PEVs it is not surprising that there are very few PEV chargers deployed. There is concern that deployment of home-based charging equipment could be an issue if PEVs are to be widespread and electricity is to be a primary fuel for light-duty transportation. A survey by Axsen and Kurani [5] found that only about 50% of new vehicle buyers have a 120 V outlet within 25 feet of their household vehicle parking space and only 35% within 10 feet. In urban areas such as San Francisco, fewer than 20% of cars are parked overnight in dedicated off-street parking. Deployment of public infrastructure at workplaces, retail establishments, and along major highways is likely to be needed to increase the utility of PEVs and to ease drivers’ "range anxiety". Charging times will be much longer than refueling a gasoline tank (tens of minutes to several hours) so chargers should be placed in locations where the driver can engage in other activities (e.g. workplace, shopping, eating out).

The supply of electricity is an important part of the equation for electrified transportation. In the near-term, the amount of electricity that would be demanded from PEVs would be a tiny fraction of total electricity generation [6]. In California, for example, charging of one million PEVs (about 4% of total cars and light trucks) would only require about 1% additional electricity generation. The timing of the demand for PEVs charge is an important issue. For example, charging during off-peak hours will tend to flatten the demand profile, reducing the need for additional generating capacity. Smart-grid technologies will allow for communication between vehicles and utilities (or grid operators), thus enabling PEV charging to be managed to ensure grid stability and minimize system costs. Given that cars are parked approximately 95 percent of the time and potentially plugged in for a large fraction of the time that they are parked, this is a real possibility.

For a PEV, the carbon intensity of electricity (grams of carbon dioxide equivalent emissions per megajoule) is higher than that of gasoline and diesel, but the carbon per unit of useful work (i.e. per mile of travel) can be much lower than that of a conventional or even hybrid vehicle. This is because electricity is an intermediate energy carrier which has already been converted from a primary energy resource, and then is used in a PEV with very high efficiency. Gasoline and diesel on the other hand are fuels that have been only slightly modified from the original primary energy resource (crude oil) to achieve specific properties suitable for internal combustion engines. They are converted at much lower efficiency to mechanical work on board the vehicle. In addition, the carbon intensity of electricity will presumably gradually be reduced as low-carbon and renewable generation increases and due to other carbon policies.

(click for larger image)

Beyond light-duty vehicles, the main energy and emissions contributions from transportation come from aviation, heavy-duty long-haul trucking and marine shipping. These sectors present significant challenges to electrification and will likely rely on high-density liquid biofuels (or potentially hydrogen) in order to reduce fuel carbon intensity. Rail, buses and delivery trucks also offer some potential for running on grid electricity.

Hydrogen as a Transportation Fuel

Hydrogen has been widely discussed as a long-term fuel option to address environmental and energy security goals [7]. Fuel cell vehicles (FCVs) that use hydrogen are significantly more efficient than conventional vehicles, using less energy to produce a mile of vehicle travel. Additionally, the fuel can be made from a wide variety of domestic and low-carbon resources, providing solutions to the oil dependency and carbon challenges. While FCVs have not yet been commercialized, several automakers have announced plans to introduce vehicles in the 2015 timeframe.

Like electricity, hydrogen is an energy carrier that is produced from a primary energy resource. Almost any energy resource can be converted into hydrogen, although some pathways are superior to others in terms of cost, environmental impacts, efficiency, and technological maturity. Currently in the US about 9 million tonnes of H2 are produced each year, mainly for industrial or refinery purposes. This would be enough to supply about 30 million FCVs. Natural gas reforming accounts for 95% of current U.S. H2 production and in the near-term should continue to be the least expensive production method. In the longer-term, continued use of fossil resources to produce H2 mainly for industrial or refinery purposes would necessitate the use of carbon capture and storage technologies to minimize the GHG emissions from H2 production. H2 can also be produced from biomass in a production process similar to that from coal (gasification). Electrolytic hydrogen production can also be an important H2 production technology in the longer-term and offers the potential for zero carbon production from renewables such as solar and wind.

Hydrogen infrastructure includes all of the components associated with producing, delivering and providing H2 to the vehicle at a refueling station and can generally be categorized into two types: on-site and central production. Onsite production uses existing energy distribution methods for electricity or natural gas to allow for H2 production at the refueling station via electrolysis or natural gas steam reforming. Central production of hydrogen would require delivery of hydrogen, via compressed-gas trucks, liquefied H2 trucks or gaseous pipelines, to the refueling station. Over the near- to medium-term, H2 infrastructure is likely to be comprised primarily of onsite H2 stations, while over time, as demand for H2 fuel increases, it is expected to transition to an infrastructure primarily composed of central production and delivery [7, 8].

One key issue regarding the deployment of hydrogen infrastructure is the "chicken-and-egg" problem: ensuring that both the H2 refueling infrastructure and FCVs will have access to the other as they are being deployed. One approach to this issue is to coordinate the deployment of vehicles and fuels in targeted locations or "lighthouse" regions. A "cluster strategy" is an even more targeted, coordinated introduction of hydrogen vehicles and refueling infrastructure in a few focused geographic areas such as smaller cities within a larger region [9].

Over the longer-term, if H2 and FCVs are widely used, the H2 infrastructure will become a massive energy system that will rival the current oil and gas infrastructure for production, delivery, storage and refueling. Estimated costs for hydrogen fuel at the large scale indicate that H2 could be cheaper per mile than even advanced gasoline vehicles [7]. However, the challenge is that in the near term, both H2 fuels and FCVs will be more expensive than conventional vehicles running on gasoline. This provides an important policy challenge to incentivize investments in lower cost, lower-carbon outcomes in the face of potentially many years of higher costs.

Hydrogen has some applicability in other transportation subsectors. Fuel cell buses and delivery trucks are potentially viable technologies. However, low energy storage density for H2 is likely to limit its use as a fuel in long-haul trucks, aircraft and marine applications.

Table 3. Resource, technology, economic and transitional issues for alternative fuels

| Hydrogen | Electricity | Biofuels | |

| Resources | Diversity of production resources | Diversity of production resources | Limits on providing enough low-carbon and sustainable biomass |

| Technologies | Production and storage are critical technologies | No major limitations | Biorefineries are critical technology |

| Economics | High initial cost; economies of scale with stations and central production | Incremental investment cost for home charging. Moderate investment cost for public charging infrastructure. | Feedstock costs are high and linked with food prices for first-generation biofuels. Biorefineries and distribution system are scale-dependent, but distribution cost can be minimized for bio- hydrocarbon fuels. |

| Transitions | Chicken-and-egg. Vehicle adoption will determine rate of infrastructure deployment; requires coordination | Vehicle adoption will determine rate of infrastructure deployment | Rapid deployment over next few decades due to federal policy. Slowed down in recent years due to concern about sustainability. |

Summary

Considering the technologies and resources that are available to us, there are several alternative fuel sources that can significantly reduce our reliance on imported oil, improve air quality, and reduce greenhouse gas emissions. However, the transition to cleaner, lower carbon fuel sources will need significant technology advancement and sustained coordination efforts among the vehicle and fuel industry and regulators over a long period of time in order to overcome market barriers, consumer acceptance, and unaccounted externalities of imported oil in their fuel price. Also, policies will be needed to ensure that the environmental performance of these new fuel sources is better than that of fossil fuels and to avoid any unintended consequences that these new fuel sources may present [3, 10].

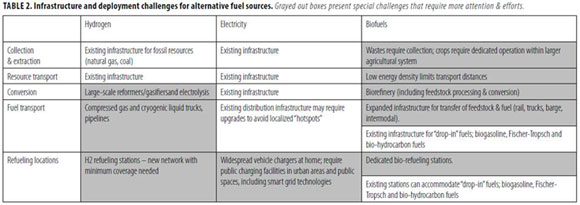

There are varying degrees of challenges associated with infrastructure design and deployment and transition to large-scale use for each of the three fuel types we have discussed. Infrastructure and transition challenges are summarized in Tables 2 and 3. A portfolio approach will give us the best chance of meeting environmental and energy security goals for a sustainable transportation future. It will be important to nurture all technologies along because we do not yet know which technologies will provide the most cost effective emissions and petroleum usage reduction while appealing to consumer preferences.

In closing, we offer three recommendations to making the transition to a future of sustainable transportation fuels:

Research is important

Fundamental and applied research is needed to improve technologies associated with fuel production, conversion, storage, and utilization as well as scientific understanding of sustainability impacts of these fuels. This research can help to guide R&D as well as investment decisions by government, industry and other stakeholders.

Policies can help level the playing field

Policies are needed to incentivize the development and use of low-greenhouse-gas/sustainable fuels through performance-based standards and market mechanisms. Policies such as emissions standards for automobiles or the low carbon fuel standard are essential for putting the different fuels (and vehicle platforms) into a common framework with which they can be assessed [11]. They allow industry the flexibility to choose different options and approaches to ensure that targets are met with lower compliance costs.

Sustainability standards should be developed

Effective sustainability policies are needed to prevent impacts on ecologically sensitive areas, air and water pollution, and competition with food resources. Continuous monitoring and assessments of unintended consequences within or beyond the production areas will be essential for the successful transition to a sustainable transportation future.

References

1. Energy Information Administration, Annual Energy Outlook 2011 with Projections to 2035. EIA, 2011.

2. Parker, N., et al., "Development of a biorefinery optimized biofuel supply curve for the Western United States." Biomass and Bioenergy, 2010, 34, pp. 1597-1607.

3. National Academy of Sciences, Liquid Transportation Fuels from Coal and Biomass Technological Status, Costs, and Environmental Impacts, 2009, NAS, Washington, DC.

4. McCollum, D. and C. Yang, "Achieving deep reductions in US transport greenhouse gas emissions: Scenario analysis and policy implications." Energy Policy, 2010, 37 (12), pp. 5580-5596.

5. Axsen, J. and K.S. Kurani, Anticipating plug-in hybrid vehicle energy impacts in California: Constructing consumer-informed recharge profiles, Transportation Research Part D, 2010, 15, pp. 212-219.

6. Lemoine, D.M., D.M. Kammen, and A.E. Farrell, "An innovation and policy agenda for commercially competitive plug-in hybrid electric vehicles," Environmental Research Letters, 2008 (1), pp. 014003.

7. National Research Council, Transitions to Alternative Transportation Technologies-A Focus on Hydrogen, 2008, NRC, Washington, DC.

8. Johnson, N., C. Yang, and J.M. Ogden, "A GIS-Based Assessment Of Coal-Based Hydrogen Infrastructure Deployment In The State Of Ohio," International Journal of Hydrogen Energy, 2008. 33 (20), pp. 5287-5303.

9. Nicholas, M.A. and J.M. Ogden, An Analysis of Near-Term Hydrogen Vehicle Rollout Scenarios for Southern California. Research Report UCD-ITS-RR-10-03, 2010, Institute of Transportation Studies, University of California, Davis.

10. Searchinger, T., et al., "Use of U.S. Croplands for Biofuels Increases Greenhouse Gases Through Emissions from Land Use Change," Science, 2008. 319 (5867), pp. 1238-1240.

11. Sperling, D. and S. Yeh, "Low Carbon Fuel Standards," Issues in Science and Technology, 2009(2), pp. 57-66.

Christopher Yang

Sonia Yeh

Institute of Transportation Studies

University of California, Davis

Davis, CA

These contributions have not been peer-reviewed. They represent solely the view(s) of the author(s) and not nexcessarily the view of APS.